3″STM1 impompo yequla enzulu

Izizathu eziphambili zokuba kutheni impompo yensimbi engenasici ayinakuqalwa kunye neendlela zokucoca:

1. Isitshixo sombane kunye neplagi ayichukumisi kakuhle (ilungisiwe okanye ifakwe endaweni yayo)

2. Umgca wolawulo watshiswa ngokukhuselekileyo (Ukutshintshwa (SAFE)

3. Isekethe engundoqo yatshiswa ngokukhuselekileyo (Replacement (SAFE)

4. I-capacitor yempompo ye-stainless steel stainless yesigaba ezibini itshisiwe (i-Replacement capacitor)

5. Inqanaba lesithathu lempompo yentsimbi engatyiwayo iphumile kwisigaba (Vula (isigaba esivulekileyo sesekethe)

I-4, impompo yentsimbi ephantsi kwamanzi ayinakusebenza

Isizathu sokuba impompo yensimbi engenastainless ingenakusebenza: indlela yokupholisa yempompo yentsimbi yentsimbi eqhelekileyo ipholile ngamanzi.Nokuba kukupholisa kwamanzi kwangaphakathi, ukupholisa kwamanzi angaphandle okanye ukupholisa amanzi angaphandle nangaphakathi kabini, amanzi ayafuneka njengendawo ephakathi ukugqibezela ukupholisa kunye nokutshatyalaliswa kobushushu bempompo yensimbi engenasiciko.Xa i-stainless steel stainless submersible pump ingasebenzi, akukho manzi okupholisa iindawo zokufudumeza ezifana ne-windings kunye neebheringi zempompo ephantsi kwamanzi, ngoko ke impompo ephantsi kwamanzi ayivumelekanga ukuba ingasebenzi.

Indlela yokupholisa amanzi angaphakathi nangaphandle kabini yepompo ephantsi kwamanzi inesiphumo esihle sokupholisa.Umgodi wangaphakathi wepompo ephantsi kwamanzi uzaliswe ngamanzi, kwaye i-stator core, i-stator winding, i-rotor core kunye ne-rotor winding (i-rotor bar kunye ne-rotor end ring) ifakwe emanzini, epholiswe ngokuthe ngqo ngamanzi kumatshini.Ubushushu obuveliswa yilahleko yentsimbi ye-stator ye-motor, ilahleko yokumelana ne-stator slot ejikajikayo kunye nenxalenye yelahleko yokumelana nesiphelo sokujija ngokuthe ngqo kudlula kumbindi we-stator kwaye idluliselwe kumanzi apholileyo aqukuqela kumphezulu ongaphandle we-stator. ukufakwa kwi-casing.Inxalenye yobushushu obuveliswa yilahleko yokumelana ne-rotor winding kunye ne-rotor iron loss idluliselwa ngokuthe ngqo kwi-stator nge-gap yomoya kwaye ithathwe ngamanzi okupholisa ngaphandle kwe-motor ngokusebenzisa i-stator;Enye inxalenye yamanzi idluliselwe kwi-rotor cavity, kunye nenye inxalenye yelahleko yokumelana nobushushu obugqithiswa yi-stator end winding ukuya kumngxuma ongaphakathi wokuzaliswa kwamanzi kunye nobushushu obuveliswa yilahleko yomatshini, idluliselwa kwi-stator core, i-casing kunye ukuthwala isihlalo ngomngxuma ongaphakathi wokuzaliswa kwamanzi, kwaye ekugqibeleni ukuya kumanzi okupholisa ngomphezulu wecasing yemoto, isihlalo esithwele kunye namanye amalungu.

Esinye isizathu sokuba ipompo ephantsi kwamanzi ingakwazi ukusebenza kukuba intloko yempompo yemoto engaphantsi kwamanzi igudile ngamanzi.Ukuba ayisebenzi ngaphandle kwamanzi, ukugaya okomileyo kuya kwenzeka phakathi kwe-pump shaft kunye ne-bearing bush.I-motor ilula kakhulu, igcwele kakhulu kwaye ishushu, kwaye injini iya kutshiswa.

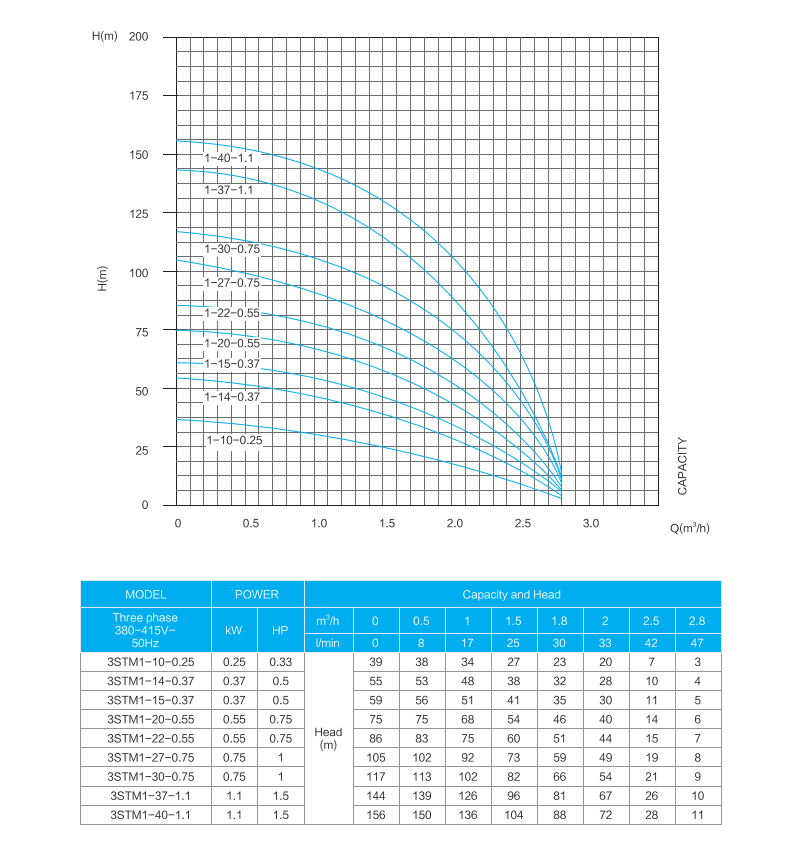

Ukusebenza kunye nemeko

Ubuninzi bobushushu bolwelo ukuya kuthi ga kwi-35 degree

Ubuninzi bomxholo wesanti: 0.25 ekhulwini

Ukuntywiliselwa okuphezulu: 80m

Ubuncinci bedayamitha yequla: 4

Iimoto kunye neMpompo

Imoto ebuyiselwa umva okanye isikrini esigcweleyo esigcweleyo

Isigaba sesithathu: 380V-415V / 50Hz

Inqanaba elinye: 220V-240V / 50Hz

Ukuxhobisa ngebhokisi yokulawula isiqalo okanye ibhokisi yolawulo oluzenzekelayo lwedijithali

Iimpompo zenziwe nge-casing stressed

Imigangatho yedimension ye-NEMA

Ukunyamezela kwegophe ngokwe-ISO 9906